Extreme Polymer Science (NSF)

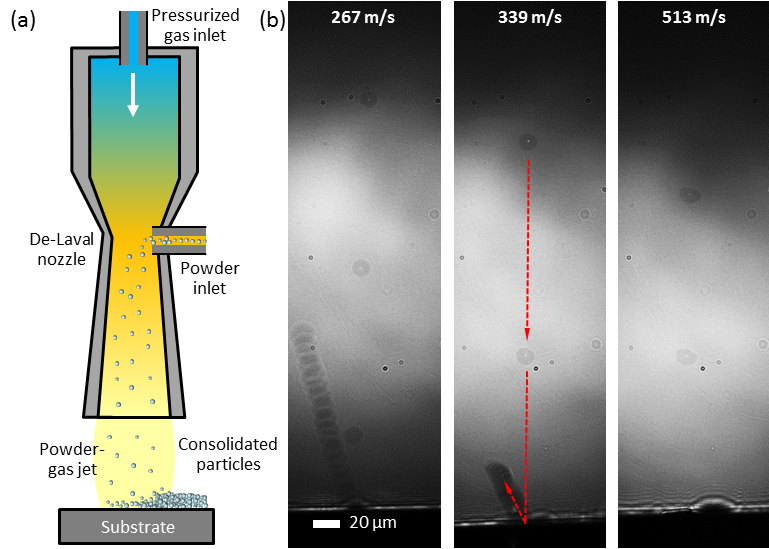

In the cold particle gas spray manufacturing technique, sub- or super-sonic spraying of feedstock powders or micro-size polymeric particles can enable unique additive processing without the use of volatile organic compounds due to the extreme deformation of the microparticles during the collisions onto a substrate. As the consolidation occurs below the microparticles’ melting temperature, extraordinary nanostructures created by the collision-induced deformation can remain and contribute to the performance of the end products. Thus, advanced additive manufacturing with the capability of nanoscale engineering of materials being deposited can be envisioned. Multiphase copolymers can serve as a promising material platform as they exhibit favorable inherent material behavior for cold particle gas spray process. This project intends to provide comprehensive and fundamental knowledge of the nanoscale morphologies of copolymers created under such process using an integrated experimental-computational approach. It is envisioned that a deeper understanding of high-strain-rate behavior of multiphase polymers will not only facilitate the development of the cold particle gas spray manufacturing technique but will also advance knowledge of materials use in extreme environments for defense applications, thereby promoting the progress of science; advancing the national health, prosperity, and welfare; and securing the national defense. The educational and outreach plan in this project includes: curriculum updates, development of a new teaching model based on student-led group projects and videography, and introduction to science and engineering for high school students through a specialized class at a local school.

In the cold particle gas spray manufacturing technique, sub- or super-sonic spraying of feedstock powders or micro-size polymeric particles can enable unique additive processing without the use of volatile organic compounds due to the extreme deformation of the microparticles during the collisions onto a substrate. As the consolidation occurs below the microparticles’ melting temperature, extraordinary nanostructures created by the collision-induced deformation can remain and contribute to the performance of the end products. Thus, advanced additive manufacturing with the capability of nanoscale engineering of materials being deposited can be envisioned. Multiphase copolymers can serve as a promising material platform as they exhibit favorable inherent material behavior for cold particle gas spray process. This project intends to provide comprehensive and fundamental knowledge of the nanoscale morphologies of copolymers created under such process using an integrated experimental-computational approach. It is envisioned that a deeper understanding of high-strain-rate behavior of multiphase polymers will not only facilitate the development of the cold particle gas spray manufacturing technique but will also advance knowledge of materials use in extreme environments for defense applications, thereby promoting the progress of science; advancing the national health, prosperity, and welfare; and securing the national defense. The educational and outreach plan in this project includes: curriculum updates, development of a new teaching model based on student-led group projects and videography, and introduction to science and engineering for high school students through a specialized class at a local school.

The objective of this work is to determine the high strain-rate dynamic characteristics of multiphase block copolymers consisting of mechanically distinctive (hard/glassy and soft/rubbery) polymer blocks, for eventual application in cold particle gas spray manufacturing. High-velocity collision experiments of single copolymer micro-particle will be performed to achieve this. Under precise collision conditions including particles? kinetic energy, angular momentum, and temperature, high-strain-rate rheology and various transitions in phase and morphology will be studied. The research team will also perform simulations based on the development of new constitutive models. Detailed high-strain-rate dynamics of deformation and the contributions from nanoscale characteristics of the polymers to the manufacturing process will be quantitatively investigated. The successful completion of this project will establish a new microscopic methodology to understand high strain-rate characteristics of multiphase polymers. The data from this research will be made available in a publicly accessible database for wider dissemination.