Kathryn Gagnon (Pre-Veterinary Science)

Kurt Hunziker (Building Construction Technology)

Corey Wrinn (Natural Resource Conservation)

Image of fracking oil rig

(Baleo, 2015)

Pennsylvanian farmers in poverty are going to sleep at night and waking up as millionaires, having leased their land to gas companies. These overnight successes are called “shaleionaires” because of their newfound wealth due to owning land above shale rock containing natural gas. Individuals receive a payment up front from drilling companies to drill under their properties, in addition to a cut of the profit that these wells generate, when the companies sell the resource. Essentially, this spontaneous income has taken these individuals from poverty, to never having to worry about money. Oil companies typically come into poor, rural towns and pay their way into setting up drilling sites to extract the natural gas they want. Shaleionaires are not the only ones economically benefitting from shale rock; in these poverty-stricken areas, the gas industry is generating jobs for all the people living in the surrounding areas. Shaleionaires, increasing job availability, and incoming profit from the extracted natural gas have resulted in an economic turnover in these areas where businesses were hurting and people were living in poverty. This can be a win-win situation for both the now wealthy local farmer, and the oil company who has access to large amounts of natural gas (Bar-On & Frank, 2010).

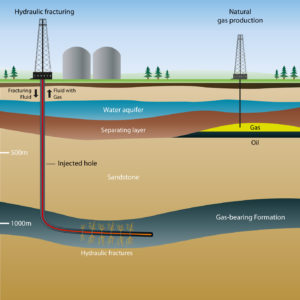

The wealth the shaleionaires have come into, and the jobs being created in these poverty-stricken areas, are because of a fairly new drilling process called hydraulic fracturing. The United States (U.S.) is taking advantage of natural gas as a new source of energy and taking advantage of the new technology of extracting it (Krupp, 2014; Zielinski, 2014). Hydraulic fracturing, or fracking, is the primary method of natural gas extraction in the U.S. The purpose is to extract natural gas from shale rock, found miles below the earth’s surface. A well, cased with steel and cement, is drilled vertically into the ground until it reaches shale rock. The well is lengthened horizontally, while water, sand and chemicals (known as “fracking fluids”) are pumped into the ground, fracturing the gas-rich shale rock. Natural gas from these fractures flow back up the well and are collected for further processing (Allen et al., 2013; Oates, 2015).

Diagram of hydraulic fracturing.

(Shale Gas International, 2014)

The U.S. has seen substantial growth in oil and gas production due to the use of hydraulic fracturing. The U.S. Energy Information Administration (EIA) estimated “…an increase in shale gas production from 5.0 trillion cubic feet (tcf) per year in 2010 to 13.6 tcf in 2035 (about 2.4 trillion barrels of oil), when shale gas is expected to account for 49% of total U.S. gas production” (Field et al., 2014 p. 955). Natural gas is mostly used to heat buildings and to generate electricity, but it has other uses, such as vehicle fuel and raw material to produce chemicals and fertilizer (EIA 2016; Siciliano, 2016). The U.S. has some of the largest reserves of gas-rich shale rock in the world, bringing potential production into almost 30 states, notably Pennsylvania, New York, Texas, Ohio, Michigan and North Dakota (Bar-On & Frank, 2010; Hirji & Song, 2015; Earthjustice, 2011).

As there is an abundance of this resource in the U.S., natural gas will become more affordable for all Americans (King, n.d.). The prices of natural gas are declining due to the affordable energy provided by fracking. In 2015, energy prices dropped by 41% due to fracking (Follett, 2016). As a domestic source of energy, the transportation and production of natural gas has proved to be less expensive than international oil imports, producing lower gas and electricity prices, an obvious perk to the American consumer (Siciliano, 2016).

The natural gas boom has caused the displacement of coal as an energy source, partly attributed to the public’s outcry for cleaner forms of energy production (Krupp, 2014; Nisbet, Dlugokencky, & Bousquet, 2014, p. 507; Siciliano, 2016; Stamford & Azapagic, 2014, p. 493). The U.S. and the U.K. utilize the environmental advantages fracking has over the country’s current source of energy: coal (Krupp, 2014). Coal-burning plants are major contributors to greenhouse gas (GHG) emission, specifically carbon dioxide. Natural gas electricity plants emit half the amount of carbon dioxide per kilowatt-hour generated than coal-burning plants (Thomasson, 2014). Switching from coal to natural gas in the U.S. has caused a 3.8% drop in carbon emissions in 2012 (Zielinski, 2014); while in 2014 GHG emissions dropped by 10% (Cass, 2016). Switching from coal to natural gas reduces the global warming potential (GWP) by 25% in the first forty years (Thomasson, 2014). Countries such as France, Bulgaria, and Germany, however, have reviewed environmental concerns related to fracking, and deemed it too hazardous to practice.

The benefits of natural gas, are usually met by environmental repercussions associated with its extraction. Though fracking results in less carbon dioxide emission, the gas that flows back in the well is mostly composed of methane- a potent GHG that has a higher potential to hold in atmospheric heat than carbon dioxide. Methane emissions are a public concern due to its presence as a powerful GHG and its contribution to global warming (Allen et al., 2013; Nisbet et al., 2014, p. 494; Stamford & Azapagic, 2014, p. 516-517; Thomasson, 2014; Zielinski 2014).

Throughout the process of fracking there is the potential for leakages of methane. There is a lack of consensus on exactly how much methane is emitted during the entire lifecycle of a fracking site. There are estimations put forth by the U.S. Environmental Protection Agency (EPA) on how much methane gas is emitted, by taking samples from certain sites and applying these values to the rest of the drills at each site in the country. But, these estimations underestimated the true amount of methane emitted at each site (Allen et al., 2015; Krupp, 2014; Peischl et al., 2015). Researchers observed leakage rates of 3.6% to 7.9% of methane (Allen et al., 2013; Omara et al., 2016, pp. 2102-2103; Thomasson, 2014) while other studies estimated that an average of 1.5% to 1.9% of all U.S. natural gas produced was lost through emissions (Krupp, 2014; Howarth, Santoro, R., & Ingraffea, 2011). In a shale region of Pennsylvania that was responsible for 2.7% of all U.S. natural gas production, 2.8% to 17.3% of methane was lost in emissions (Peischl, 2015). With varying reports of exact methane emissions at fracking sites, it is hard to assess the exact impact the growth of the industry will have on the environment, but all sources point to a negative outcome if current methane emission remains the same.

Methane emission to the atmosphere has been considered by many to be one of the greatest environmental challenges of the 21st century (Teasdale, Hall, Martin, & Manning, 2014) as methane contributes to the overall greenhouse gas footprint from human activities 1.4 to 3 times more than direct carbon dioxide emission. The oil and gas industry has been a major contributor to the amount of methane being emitted into the atmosphere, with one-third of the total methane emissions in the U.S. being attributed to fracking in the oil and gas industry (Krupp, 2014). Because of this, fracking has a GHG footprint 22% to 43% higher than other forms of gas extraction (Omara et al., 2016; Howarth et al., 2011).

Hazardous gases, such as volatile organic compounds (VOCs) and methane, are released into the atmosphere when a well is reused. Due to the gas emitted during this process, increased air pollution is found in areas surrounding fracking sites, leaving the general population exposed to these pollutants (Field et al., 2014; Meng, 2015). Communities in the vicinity of fracking sites have reported various health issues attributed to the pollution caused by methane emissions and VOCs from natural gas production, such as respiratory, nervous, and immune system disorders (Field et al., 2014; Fox, et al., 2010; Meng, 2015). While advocates of fracking have described it as a clean, low carbon energy supply, other researchers have seen irreversible damage due to increased air pollution (Field et al., 2014).

Although methane emissions present environmental and health threats, fracking still has an advantage over the use of coal. Eco-friendly improvements can be made to the industry to reduce methane emissions. To prevent the detrimental environmental impacts from methane emitted during hydraulic fracturing, the U.S. government must mandate onsite use of green completion infrastructure to reduce methane emissions.

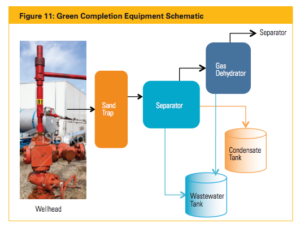

Completion is the process by which a wellbore is cleaned of debris after the well is hydraulically fractured, before it can be hydraulically fractured again. Completion is usually done by draining fracking fluids to an open pit or tank and directing the associated methane gas and VOCs to a gas vent or flare (Harvey, Gowrishankar, & Singer, 2012). Flaring is the most common method of completion in the U.S. because it is one of the easier and cheaper methods of completion. Flaring off involves funneling unwanted natural gas through a separate pipe, and burning it off into the atmosphere (Natural Gas Now, 2014; Fox et al.,, 2010). Though flaring is easier and cheaper for oil and gas companies to use for completion, it is not the most environmentally friendly, because the burning of the gas still results in methane and carbon dioxide being released into the environment (Kahya, 2013). The Greenhouse gas inventory conducted by the EPA estimated that during well completions, 68 billion cubic feet (Bcf) of methane is emitted per year, and green completions have the promise of controlling a portion of those emissions (Harvey et al., 2012).

Green completion drastically reduces a fracking companies’ methane emissions by capturing natural gas that flows back to the wellhead after completion, and separating it into a tank (Allen et al., 2013; Howarth et al., 2011; Krupp, 2014; Field et al., 2014; Omara et al., 2016). This method of completion involves additional equipment to separate the gases and solids expelled during well completion, to allow the gas to be sent into a production pipeline rather than being vented or flared into the atmosphere (Harvey et al., 2012; Stamford & Azapagic, 2014). Once the methane is captured, it can be sold, used as fuel, or re-injected into the well (Harvey et al., 2012).

Green completion equipment schematic

(Harvey et al., 2012)

Researchers observed three sites of natural gas extraction through fracking, where 3 out of 4 sites used greenhouse completion method. The one site that used direct flaring of the gases had the largest observed methane emission rate (Omara et al., 2016, p. 2104). The site that used direct flaring of the gas after completion emitted 46.4 kilograms of methane per hour; compared to the sites that use green completion that had emission rates of 5.6 to 15.2 kilograms of methane per hour (Omara et al., 2016, p. 2103). Researchers consistently saw that the sites with lower methane emission were sites that use green completion, and that flaring resulted in much larger methane emissions (Allen et al., 2013; Omara et al., 2016).

An estimated 90% of methane emitted during the completion process can be captured by implementing green completion (Thomasson, 2014). Emissions from well completions have been known to vary, but each time green completion is implemented, it is highly effective at reducing methane emission. It is predicted that in the U.S. green completion could reduce annual methane emissions by 1.0 to 1.7 million short tons (Field et al., 2014).

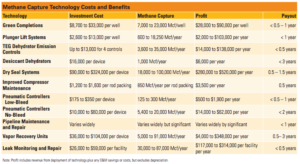

Adopting this method of completion proves to be much more advantageous economically because more natural gas is available to sell, rather than simply flaring off (Natural Gas Now, 2014). Companies that implement green completion have seen a large amount of gas recovery; for example, BP used green completions at 106 wells and recovered 3,300 Mcf (1,000 cubic feet) per well. Devon Barnett Shale used green completions at 1,798 wells, and recovered 6,300 Mcf per well (Harvey et al., 2012). Companies would also see increased revenue from using green completion. Capturing natural gas at the wellhead by green completion would cover the cost it would take to switch to this method (O’Sullivan & Paltsev, 2012; Thomasson, 2014). Studies show that green completion would be more cost effective over time, than continuing to allow sites to operate as they have been, contributing to methane emissions (O’Sullivan & Paltsev, 2012). Green completion is now required in Colorado and Wyoming, and has been successfully implemented and cost effective for these states (Thomasson, 2014). Studies show that more than $2 billion annually can be brought in as additional revenue by capturing and selling the fugitive methane emissions through green completion (Harvey et al., 2012). Based on capture rates of 7,000 to 23,000 million cubic feet (Mcf) of methane per well, there is an opportunity for gas companies to make $28,000 to $90,000 per gas well by implementing green completion (Harvey et al., 2012). For existing fracking sites that do not have green completion equipment, the equipment can be rented, with the investment being paid off immediately. The equipment can also be purchased and the investment for this equipment would be paid off within a year (Harvey et al., 2012). Researchers found companies who implemented green completion in 2005 made more than $65 million in profit. There is incentive economically and environmentally to implement green completion in every state in the U.S. because of the vast evidence of reduced methane emissions by this method, and the large profit that can be generated by the gas captured during green completion (Harvey et al., 2012; Thomasson, 2014).

Potential revenue for green completion and other methane emission reducing technology.

(Harvey et al., 2012)

Fracking is gaining popularity, especially in the U.S., for many reasons both economically and environmentally (Bar-On & Frank, 2010; Field et al., 2014; Krupp, 2014; Zielinski, 2014). Compared to coal, natural gas is a greener form of energy, and fracking is a more economical sustainable way of obtaining energy (Thomasson, 2014). Fracking is not perfect, and comes with its own environmental hazards relating to methane emissions. Methane emissions from fracking are dangerous and are hindering a positive view on this form of energy production, in light of health risks and environmental issues (Field et al., 2014; Stamford & Azapagic, 2014). Yet, these environmental implications due to methane emission during fracking can be drastically reduced by the use of green completion (Howarth et al., 2011; Krupp, 2014; Field et al., 2014; Omara et al., 2016). Green completion has proven to drastically reduce methane emission during completion, and generate profit for the gas companies that implement it (O’Sullivan & Paltsev, 2012; Thomasson, 2014). If green completion is made legally required at the state level with existing fracking sites and potential fracking sites, the levels of methane emission will drop significantly, and gas companies will generate more profit than if they continue to use flaring. This will create a better future for the earth and the environment, and a healthier future for the people; while still keeping gas prices low, generating profits, and making jobs in areas where fracking is done.

REFERENCES

Allen, D. T., Torres, V. M., Thomas, J., Sullivan, D. W., Harrison, M., Hendler, A., . . . Seinfeld, H. (2013). Measurements of methane emissions at natural gas production sites in the United States. Proceedings of the National Academy of Sciences, 110(44), 17768-17773. doi:10.1073/pnas.1304880110.

Bar-On, S., & Frank, M. (Producers). (2010, Nov 12). 60 Minutes [Television broadcast]. Washington DC: CBS News.

Cass, Oren. (2016). Reality check: fracking, not solar power, is reducing U.S. carbon-dioxide emissions. Manhattan Institute, 1-5. Retrieved from http://www.manhattan-institute.org/sites/default/files/issues2016-2.pdf

Earthjustice. (2011). Fracking across the United States. Retrieved from http://earthjustice.org/features/campaigns/fracking-across-the-united-states

EPA. (2014). Overview of greenhouse gases. Environmental Protection Agency. Retrieved from https://www.epa.gov/ghgemissions/overview-greenhouse-gases

Field, R. A., Soltis, J. & Murphy, S. (2014). Air quality concerns of unconventional oil and natural gas production. Environmental Science: Processes & Impacts. 16: 954-969. doi:10.1039/c4em00081a.

Follett, A. (2016). Average US gasoline price drops below $2 a gallon due to fracking. The Daily Caller. Retrieved from http://dailycaller.com/2016/01/04/average-us-gasoline-price-drops-below-2-a-gallon-due-to-fracking

Fox, J., Gandour, M., Adlesic, T., & Sanchez, M., International WOW Company., Gasland Productions., HBO Documentary Films., … New Video Group. (2010). Gasland: Can you light your water on fire?. New York, NY: Docurama Films.

Harvey, S., Gowrishankar, V., & Singer, T. (2012). Leaking profits: the U.S. oil and gas industry can reduce pollution, conserve resources, and make money by preventing methane waste. NRDC. Retrieved from https://www.nrdc.org/sites/default/files/Leaking-Profits-Report.

Hirji, Z. & Song, L. (2015) Map: the fracking boom, state by state. Inside Climate News. Retrieved from https://insideclimatenews.org/news/20150120/map-fracking-boom-state-state

Howarth, R.W., Santoro, R., & Ingraffea, A. (2011). Methane and the greenhouse-gas footprint of natural gas from shale formations. Climate Change. 106: 679. doi:10.1007/s10584-011-0061-5

Kahya, D. (2013). Fracking: flaring and why it matters. EnergyDesk, GreenPeace. Retrieved from http://energydesk.greenpeace.org/2013/05/10/fracking-flaring-matters/

King, H. (n.d.). Directional and horizontal drilling in oil and gas wells. Retrieved from http://geology.com/articles/horizontal-drilling.

Krupp, F. (2014). Don’t just drill, baby- drill carefully. Foreign Affairs. Retrieved from https://www.foreignaffairs.com/articles/2014-04-17/dont-just-drill-baby-drill-carefully.

Natural Gas Now. (2014). Flaring vs. green completion. Retrieved from http://naturalgasnow.org/hydraulic-fracturing-2/flaring-versus-green-completions.

Nisbet, E. G., Dlugokencky, E. J., & Bousquet, P. (2014). Methane on the rise–again. Science, 343(6170), 493-495. doi:10.1126/science.1247828

Oates, R. (2015). Cracking the fracking: everything you need to know (Infographic). Arbtech. Retrieved from https://arbtech.co.uk/cracking-fracking-everything-need-know-infographic/.

Omara, M., Sullivan, M. R., Xiang, L., Subramanian, R., Robinson, A. L., & Presto, A. A. (2016). Methane emissions from conventional and unconventional natural gas production sites in the Marcellus Shale Basin. Environmental Science & Technology, 50(4), 2017-2099. doi:10.1021/acs.est.5b05503

O’Sullivan, F. & Paltsev, S. (2012). Shale gas production: potential versus actual greenhouse gas emissions. Environmental Research Letters. 7:4. doi:10.1088/1748-9326/7/4/044030

Peischl, J., Ryerson, T. B., Aikin, K. C., de Gouw, J. A., Gilman, J. B., Holloway, J. S., Lerner,… Parrish, D. D. (2015). Quantifying atmospheric methane emissions from the Haynesville, Fayetteville, and northeastern Marcellus shale gas production regions. Journal of Geophysical Research: Atmospheres, 120, 2119–2139. doi:10.1002/2014JD022697.

Meng, Qingming (2015). Spatial analysis of environment and population at risk of natural gas fracking in the state of Pennsylvania, USA, Science of The Total Environment, 515–516,198-206, http://dx.doi.org/10.1016/j.scitotenv.2015.02.030.

Siciliano, J. (2016). Fracking has been good for the environment. Washington Exclaimer. Retrieved from http://www.washingtonexaminer.com/moniz-fracking-has-been-good-for-the-environment/article/2599392

Stamford, L., & Azapagic, A. (2014). Life cycle environmental impacts of UK shale gas. Applied Energy, 134, 506-518. doi://dx.doi.org/10.1016/j.apenergy.2014.08.063

Teasdale, C. J., Hall, J. A., Martin, J. P., & Manning, D. A. C. (2014). Ground gas monitoring: implications for hydraulic fracturing and CO2 storage. Environmental Science &Technology. 48: 13610-13616. dx.doi.org/10.1021/es502528c

Thomasson, C. (2014). Natural gas: the newest danger for global warming. Environmental Health Policy Institute. Retrieved from http://www.psr.org/environment-and-health/environmental-health-policy-institute/responses/natural-gas-the-newest-danger-global-warming.html

Zielinski, S. (2014). Natural gas really is better than coal. Smithsonian. Retrieved from http://www.smithsonianmag.com/science-nature/natural-gas-really-better-coal-180949739.

info slot gacor hari ini

bocoran slot online

info rtp slot

live rtp slot

بازار آنلاین لوازم یدکی خودرو

ایموجو رسانه تخصصصی دنیای بازی

https://emojo.ir/

ایموجو رسانه تخصصصی دنیای بازی از سال Û±Û³Û¹Û¸ Ùعالیت خود را آغاز نمود. در ایموجو شما Ù…ÛŒ توانید جدیدترین اخبار دنیای بازی، آموزش بازی ها، نقد Ùˆ بررسی بازی Ùˆ راهکارهایی برای رÙع مشکلات بازی ها را بیابید Ùˆ به ساده ترین Ø´Ú©Ù„ ممکن، بازی مورد علاقه خود را دانلود نمایید. در Ùروشگاه ایموجو، Ù…ÛŒ توانید کنسول پلی استیشن Ûµ Ùˆ سایر بازی ها را با قیمت مناسب خریداری نمایید.

دستر Says:

June 25th, 2022 at 1:32 am

خدمات کارخانه دستر تولید انواع ملزومات خواب اعم از انواع روتختی، انواع سرویس های Ù„ØاÙØŒ انواع سرویس های کاور Ù„ØاÙØŒ انواع سرویس های نیم ست وملØÙه، انواع روتختی بهاره، Ù„Øا٠لایت، کاور تشک

سÙری، انواع بالش، انواع روبالشتی، و… در تمامی ابعاد Ùˆ مناسب هر نوع سلیقه با بهترین متریال Ùˆ Ú©ÛŒÙیت در خور شان ایرانی می‌باشد

سایت دستر

https://www.dastherco.com/

Profesyonel

نکات مهم در هنگام خرید اسپیکر

در هنگام خرید اسپیکر باید به نکات زیادی توجه کرد ØŒ این نکات طی٠گسترده ای از نیازهای کاربران را پوشش Ù…ÛŒ دهد ØŒ توجه زیاد به طراØÛŒ Ùˆ زیبایی اسپیکر ذهن ما را از ویژگی ها Ùˆ مشخصات ÙÙ†ÛŒ اسپیکر دور Ù…ÛŒ کند Ùˆ شاید نتوان در هنگام خرید اسپیکر بهترین انتخاب را داشت.در ادامه به بررسی برخی از این ویژگی های مهم Ù…ÛŒ پردازیم :

توان واقعی:

توان واقعی اسپیکر با میزان بلندی صدا رابطه مستقیمی دارد واØد آن برØسب وات است Ùˆ با R.M.S نشان داده Ù…ÛŒ شود.در هنگام خرید اسپیکر به عددی Ú©Ù‡ پس از عبارت R.M.S نوشته Ù…ÛŒ شود توجه کنید این عدد بیانگر توان واقعی اسپیکر یا بلندگو است.به میزان توان الکتریکی Ú©Ù‡ به بلندگو منتقل Ù…ÛŒ شود تا Øداکثر قابلیت خود را ارائه دهد توان واقعی اسپیکر Ú¯Ùته Ù…ÛŒ شود.بسیاری از تولید کننده ها Ùˆ کمپانی های ساخت اسپیکر برای Ù…Øاسبه توان اسپیکر از Øرو٠P.M.P.O استÙاده Ù…ÛŒ کنند Ú©Ù‡ به معنی Øداکثر توانی است Ú©Ù‡ بلندگو Ù…ÛŒ تواند در یک زمان کوتاه به پخش صدا یا موزیک بپردازد بدون اینکه آسیبی به آن وارد شود.اگرچه نمیتوان از تولید کنندگان Ùˆ کمپانی های تولید کننده انواع اسپیکر خرده گرÙت این عامل به بیشتر یک جنبه تبلیغاتی دارد Ú©Ù‡ در هنگام خرید اسپیکر باید به آن توجه نمود.

عمر باتری:

یکی از ویژگی های بسیار مهم Ù…Øسوب Ù…ÛŒ شود چرا Ú©Ù‡ بسیاری از اÙراد علاقه مند به شنیدن صدا Ùˆ موسیقی مورد نظر در مکان هایی هستند Ú©Ù‡ شاید دسترسی به برق شهری امکان پذیر نباشد. پس در هنگام خرید اسپیکر به ظرÙیت باتری آن توجه کنید معمولا انواع اسپیکر بلوتوثی دارای ظرÙیت قابل قبولی هستند اما اگر از آن دسته اÙرادی هستند Ú©Ù‡ مدام در Øال سÙر هستید در هنگام خرید اسپیکر به ظرÙیت Ùˆ میزان نگهداری شارژ باتری توجه کنید.

چند کاناله بودن اسپیکر

یک اسپیکر چند کاناله توانایی تولید صدا با جزئیات Ùˆ اÙکت های بیشتری را دارد در نتیجه قابلیت پخش صدای با Ú©ÛŒÙیتی را دارد.اکثر اÙراد علاقه زیادی به بیس بالا بلندگو دارند، اگر از این دسته اÙراد هستید خرید اسپیکرهای چند کاناله بهترین انتخاب است.اسپیکرهای استاندارد Ùˆ معمولی به صورت 2.0 کاناله هستند این بدان معناست Ú©Ù‡ این اسپیکرهای توانایی تولید صداهای بم را ندارند وتنها از دو بلندگو برای پخش صدا استÙاده Ù…ÛŒ کنند.در مقابل اسپیکرهای 2.1 کاناله علاوه بر 2 بلندگو از یک ساب ووÙر استÙاده میکنند Ú©Ù‡ باعث پخش صداهای بم در Ùرکانس پایین را دارند. با پیشرÙت تکنولوژی اسپیکرهایی با تعداد کانال های بیشترمثل 1/7 کاناله نیز وجود دارد Ú©Ù‡ به این معناست دارای 7 بلندگو Ùˆ یک ساب ووÙر است.