Hydraulic systems play an integral role in various industrial applications, such as construction, agriculture, and manufacturing. These systems require precise control of pressure and flow to ensure optimal performance and efficiency. One critical component that helps regulate hydraulic system pressure is the pressure compensator function. In this outline, we will discuss what pressure compensator function is and its importance in hydraulic systems. We will also explore the benefits, applications, and maintenance requirements of pressure compensator function, as well as its impact on system performance and efficiency.

Understanding Pressure Compensator Function

A pressure compensator is a device used in hydraulic systems to maintain a consistent pressure level in the system. It is an essential component for the safe and efficient operation of hydraulic systems.

The pressure compensator works by sensing the system pressure and adjusting the flow of hydraulic fluid to maintain a constant pressure level. When the system pressure reaches a pre-determined level, the pressure compensator adjusts the flow of hydraulic fluid to prevent the pressure from rising any further. Similarly, if the system pressure drops below the set level, the pressure compensator adjusts the flow to increase the pressure.

There are different types of pressure compensators available, including mechanical, electrical, and hydraulic. Mechanical pressure compensators are the simplest and most commonly used type. They use a spring-loaded valve to adjust the flow of hydraulic fluid. Electrical pressure compensators use electronic sensors to adjust the flow, while hydraulic pressure compensators use hydraulic pressure to control the flow.

The type of pressure compensator used depends on the specific requirements of the hydraulic system. Mechanical pressure compensators are suitable for simple systems that do not require precise pressure control. Electrical pressure compensators are ideal for systems that require precise control and rapid response times. Hydraulic pressure compensators are used in heavy-duty applications where the system pressure is high.

In addition to maintaining a constant pressure level, pressure compensators also provide overload protection to the system. They prevent the pressure from rising too high and causing damage to system components. Pressure compensators also reduce the risk of leaks and other failures in the system by reducing stress on the components.

Overall, pressure compensator function is an essential feature of hydraulic systems. It helps to ensure the safe and efficient operation of the system, as well as extending the lifespan of system components. Proper understanding and use of pressure compensator function can result in improved productivity, reduced maintenance costs, and increased safety.

Benefits of Pressure Compensator Function

Hydraulic systems rely on precise pressure control to function effectively and safely. This is where the pressure compensator function comes in, offering a range of benefits that make it an essential component in many hydraulic systems.

One of the primary benefits of pressure compensator function is improved efficiency. By regulating system pressure, the pressure compensator ensures that the hydraulic pump only works as hard as necessary to meet system demands. This means that the pump doesn’t waste energy by running at full capacity when it’s not needed, reducing energy consumption and associated costs.

Another key benefit of pressure compensator function is increased safety. Hydraulic systems can be dangerous if pressure isn’t regulated correctly, with the potential for equipment failure or injury. The pressure compensator helps prevent these risks by ensuring that system pressure remains within safe operating limits.

In addition, pressure compensator function can reduce wear and tear on system components. By regulating pressure, the pressure compensator prevents excessive force from being exerted on components such as hoses, valves, and cylinders. This can extend the lifespan of these components and reduce the need for costly repairs or replacements.

Overall, the benefits of pressure compensator function can translate to increased productivity and reduced maintenance costs, making it an essential component in many hydraulic systems.

Pressure Compensator Function and System Performance

The pressure compensator function is a critical component in hydraulic systems, as it directly affects system performance and efficiency. When hydraulic systems operate under varying loads, the pressure changes as a result. Pressure compensators adjust the pressure to match the system’s load, ensuring that the system operates at optimal efficiency.

By adjusting the pressure compensator function, operators can optimize system performance for specific applications. For example, in applications where speed is crucial, the pressure compensator can be adjusted to ensure that the system operates at maximum flow rate. Alternatively, in applications where precision is important, the pressure compensator can be adjusted to maintain a consistent flow rate.

The pressure compensator function can also impact the energy efficiency of hydraulic systems. By maintaining a consistent pressure and flow rate, the system operates more efficiently, reducing energy consumption and operating costs.

However, improper adjustment of the pressure compensator function can result in decreased system performance and efficiency, as well as increased wear and tear on system components. Therefore, it is important to understand how to properly adjust and maintain the pressure compensator function for optimal performance and longevity.

Importance of Proper Adjustment and Maintenance

Proper adjustment and maintenance of pressure compensator function are essential for optimal system performance and longevity. Over time, the settings of the pressure compensator may become misaligned or the components may wear down, which can lead to issues such as reduced efficiency, increased energy consumption, and premature component failure.

To ensure that the pressure compensator is functioning correctly, regular maintenance and adjustment is necessary. This includes monitoring pressure levels and flow rates, checking for leaks, and making any necessary adjustments to the pressure compensator settings.

It is important to consult the manufacturer’s guidelines for specific maintenance and adjustment procedures, as the methods may vary depending on the type and model of pressure compensator used in the system. In addition, it is recommended to have a trained professional perform any maintenance or adjustment procedures to avoid potential safety hazards or damage to the system.

By maintaining and adjusting the pressure compensator function as needed, the hydraulic system can operate at optimal levels of performance and efficiency, reducing energy consumption and maintenance costs while extending the lifespan of system components.

Applications of Pressure Compensator Function

Pressure compensator function is an essential component in hydraulic systems, and it has many applications across different industries. Here are some of the industries and applications that benefit from the use of pressure compensator function in their hydraulic systems:

- Construction: The construction industry relies heavily on hydraulic systems, and pressure compensator function is particularly useful in this field. Hydraulic systems in construction equipment, such as cranes and excavators, require precise control of pressure and flow rates. Pressure compensator function helps to maintain constant pressure in the hydraulic system, which is necessary for the safe and efficient operation of these machines.

- Manufacturing: Hydraulic systems are commonly used in manufacturing equipment, such as presses, injection molding machines, and assembly machines. These systems require precise control of pressure and flow rates to ensure that the manufacturing process runs smoothly and efficiently. Pressure compensator function helps to regulate the pressure and flow of hydraulic fluid, which ensures that the manufacturing equipment operates at optimal performance.

- Agriculture: The agriculture industry uses hydraulic systems in a variety of applications, including tractors, harvesters, and irrigation systems. Pressure compensator function is particularly useful in irrigation systems, where it helps to maintain a constant pressure in the hydraulic system. This is important for ensuring that water is distributed evenly across the crops, which is essential for crop growth and yield.

- Aerospace: The aerospace industry requires hydraulic systems for a variety of applications, including landing gear, flaps, and brakes. Pressure compensator function is necessary in these systems to maintain a constant pressure, which is essential for the safe and efficient operation of aircraft.

- Oil and Gas: The oil and gas industry relies heavily on hydraulic systems for a variety of applications, including drilling and extraction equipment. Pressure compensator function is particularly useful in hydraulic systems used in drilling equipment, where it helps to regulate the pressure of hydraulic fluid, which ensures that the drilling process runs smoothly and efficiently.

In addition to these industries, pressure compensator function has applications in many other fields, such as marine, transportation, and mining. Regardless of the application, pressure compensator function is essential for ensuring that hydraulic systems operate at optimal performance and efficiency.

Resources and Additional Information

To ensure proper maintenance and adjustment of pressure compensator function in hydraulic systems, it is important to stay up-to-date with industry best practices and regulations. Here are some resources and additional information that can help:

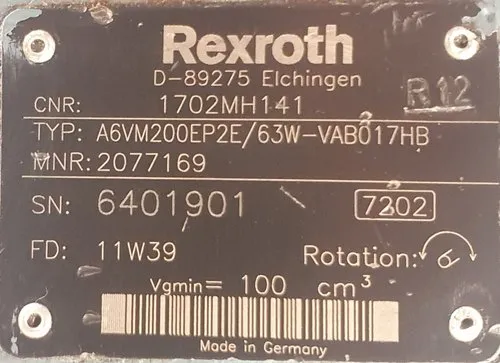

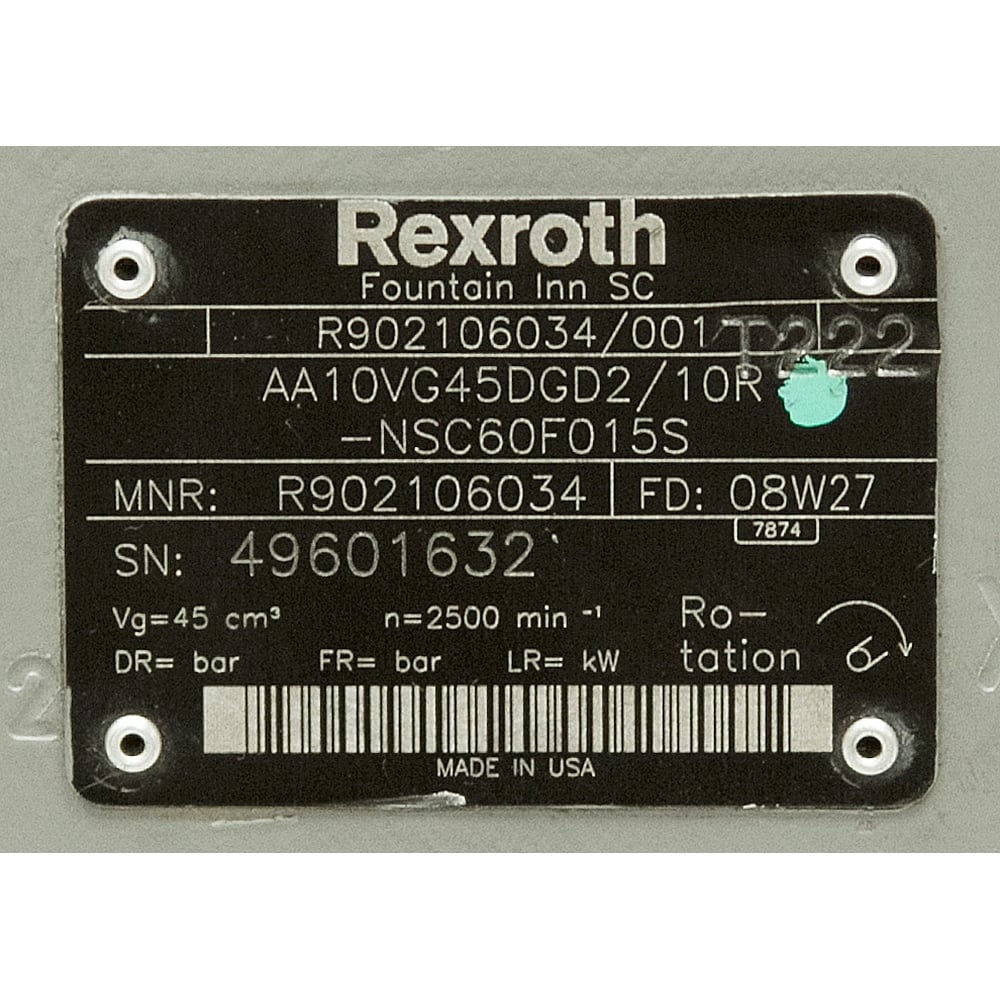

- Manuals and technical specifications: Manufacturers of hydraulic systems and components often provide detailed manuals and technical specifications that can be used as references for proper maintenance and adjustment of pressure compensator function.

- Instructional videos: Many manufacturers also provide instructional videos that demonstrate how to properly adjust and maintain pressure compensator function in their hydraulic systems.

- Industry associations: Joining industry associations such as the International Fluid Power Society (IFPS) can provide access to resources and training opportunities related to hydraulic systems.

- Trade publications: Trade publications such as Hydraulics & Pneumatics and Fluid Power World often feature articles and information on best practices for maintaining and adjusting pressure compensator function in hydraulic systems.

- Training courses: Many manufacturers and industry associations offer training courses on hydraulic system maintenance and adjustment, including pressure compensator function.

By utilizing these resources, hydraulic system operators can stay informed on best practices and regulations related to pressure compensator function, ensuring optimal system performance and longevity.

Conclusion

In this outline, we’ve explored the importance of pressure compensator function in hydraulic systems. We’ve discussed what pressure compensator function is and how it works to regulate hydraulic system pressure. We’ve also identified the key benefits of using pressure compensator function in hydraulic systems, such as improved efficiency, increased safety, and reduced wear and tear on system components.

Additionally, we’ve discussed how adjusting the pressure compensator function can optimize system performance for specific applications, and provided guidance on how to properly adjust and maintain pressure compensator function to ensure optimal performance and longevity.

Furthermore, we’ve explored various applications of pressure compensator function in industries such as agriculture, construction, and manufacturing. We’ve discussed how pressure compensator function can improve efficiency and safety in these applications.

By utilizing the information and resources provided in this outline, hydraulic system operators can better understand the importance of pressure compensator function and how to optimize their system’s performance for their specific applications. It’s crucial to prioritize proper adjustment and maintenance of the pressure compensator function to ensure optimal performance and longevity, and to stay up-to-date with industry best practices and regulations.

In conclusion, pressure compensator function is a critical component of hydraulic systems, and understanding its function and benefits is essential for optimizing system performance and ensuring the safety of operators and equipment.