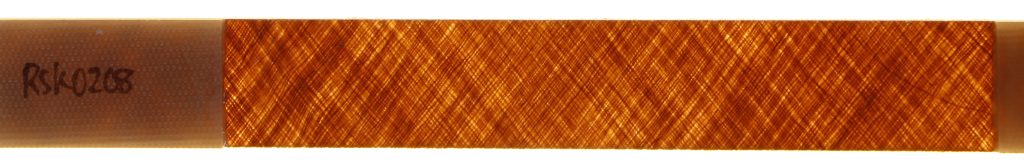

In order to calculate precise stress tensors from Classical Lamination Theory, we need a very accurate way to measure the angle of fibers in the flax composites we are testing. Building upon the work of Yosuke Ueki, I have developed a methodology with which to do this using the Fast Fourier Transform.

(1) Take a high quality image, using a light table and a standard 35mm high megapixel camera (I used the Sony a7rii)

(2) My MATLAB program squares the image, trims the edges and takes the image intensity (grayscale image).

(3) MATLAB already has FFT functions built in. I’m not going to get into this here, but if you don’t know much about Fourier Transforms there is a wealth of information online, including a super great MOOC through Stanford University. The coolest part (I think) is that this technique was first proposed in the early 1800s for solving the heat equation, but was re-popularized almost 200 years later(!) because of what internet technologies have required in terms of signal processing. Math! wow!

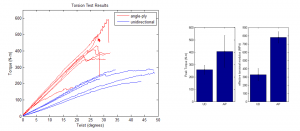

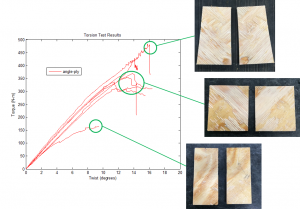

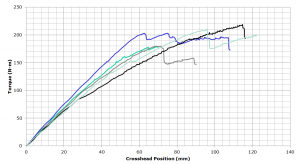

(4) From here, we can build a histogram of the fiber angles at each point. In this example, the biaxial fabric orientation is (+52.4, -51.8) degrees. We can also use this data to compare the variance in fiber angle across different manufacturing techniques, but we must use caution as you can see there is a bit of noise. I haven’t used any filters here, but one of the nice things about FFT is the capability to use filters on the image. (I do use a high-pass filter when I calculate average fiber angle.)

TLDR: FFT a simple-enough, super-quick way to measure fiber orientation in a composite laminate without any high-tech equipment- just using an ordinary camera and a light table.