The tenth week of the DesignBuild was unlike any other week, starting off with a rare event, a total solar eclipse, at 3:27pm on Monday. The eclipse was visible from three surrounding states: Vermont; New Hampshire; and New York, so we were given an optional class day for an opportunity to watch it. Picking up a free pair of eclipse glasses from UMass, I drove north to Rock River in Vermont where I watched the eclipse while listening to the water flow and admiring nature. Watching how the moon slowly began to cover the sun and then eventually turning everything momentarily dark, was an eye-opening experience and a humble break from the work rhythm of the studio.

On Wednesday we were back in class as usual, beginning the day with an in-detailed conversation about energy modelling led by Mark Rosenbaum. Using his proprietary spreadsheet, we went over the whole process for calculating the net energy consumption of a house by unpacking the different variable and constant components that play a role in the energy cycle of a home. Analyzing energy systems is essential in designing net zero architecture and hence minimizing the impact of the build on our environment.

While on one hand, there is a huge responsibility to build net positive buildings, on the other hand, few of us understood and had been exposed to the application of energy calculations in the built environment. As such, this conversation involving all working groups (not just the team responsible for energy modelling) was extremely insightful and necessary to all of our careers.

To wrap up the week we delved deeper into the structure and envelope of the home with a group discussion led by Professor Kent Hicks finalizing unclear components: the type of insulation, roof and floor trusses, as well as roof type. Through this we were finally able to identify the effects of the loads of each component in the assembly, the connections between wall to roof and wall to floor, and the vapor barrier wrapping the whole structure. Understanding the assembly of a home is essential for ensuring protection from the external natural elements, home efficiency, thermal transmissions and comfort, as well as durability of a home.

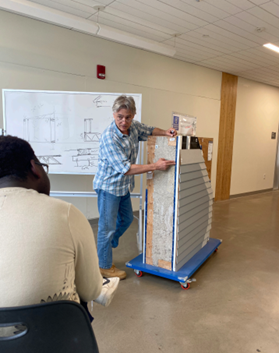

Unlike what we had initially planned, a generous donation of wood fiber batt insulation led us to abandon the choice to use a densely packed cellulose wall. Both having the same resistance to heat flow, simultaneously sequestering carbon, and having similar application processes. The switch in insulations was relatively effortless requiring few changes at this stage. Moreover, we were also able to use a physical model of a double 2×4 dense packed cellulose high performance wall to rapidly understand and study the wood batt assembly. The specificity of studying a constructed wall with manufactured materials was insightful and helped bridge the gap between theory and application.

Furthermore, to go with the double pitch offset gable roof of the design, we learned about a unique solution involving the implementation of two different types of trusses, both sets designed to accommodate their appropriate roof slope and load. Through the process of understanding the trusses, we were introduced to truss technical drawings and important measurements assigned to each truss including the deflection and snow load, to ensure that the structure of the trusses is strong enough to withstand the code required parameters. The design and construction of the trusses is undertaken by UFP Site Built under the auspices of Brian Tetreault and is vital to preserve the structural durability of the home and protect the safety of its inhabitants.

Lastly, we identified the continuous air barrier around the building envelope created by a thick layer of Zip sheathing. Moreover, this sheathing also aids in stabilizing and aligning the connections of the whole structure. This discussion was critical for deviating from the conventional uses of each material and instead, identifying its properties and thus, its role in the assembly.

The discussion was extremely specific to our design, bridging the gap between building science theory and actual application; simultaneously taking us through the thinking process of the assembly, from component to component to understand how exactly they are interacting. Next, we take on the challenge of designing aesthetic protection for insects to keep our walls healthy for as long as possible!